新一代激光扫描仪

The measurement of wool fibre diameter can be conducted through four distinct methods as delineated by the International Wool Textile Organisation (IWTO). AWTA Ltd employees the IWTO-12 Laserscan fibre diameter analyser method for fibre diameter certification and fleece measurement services.

In 1972, CSIRO initiated the development of the first Laserscan, establishing the foundation and obtaining approval for the method from the IWTO. Subsequently, in 1996, AWTA Ltd acquired the rights to manufacture and sell the Laserscan and continued its further development.

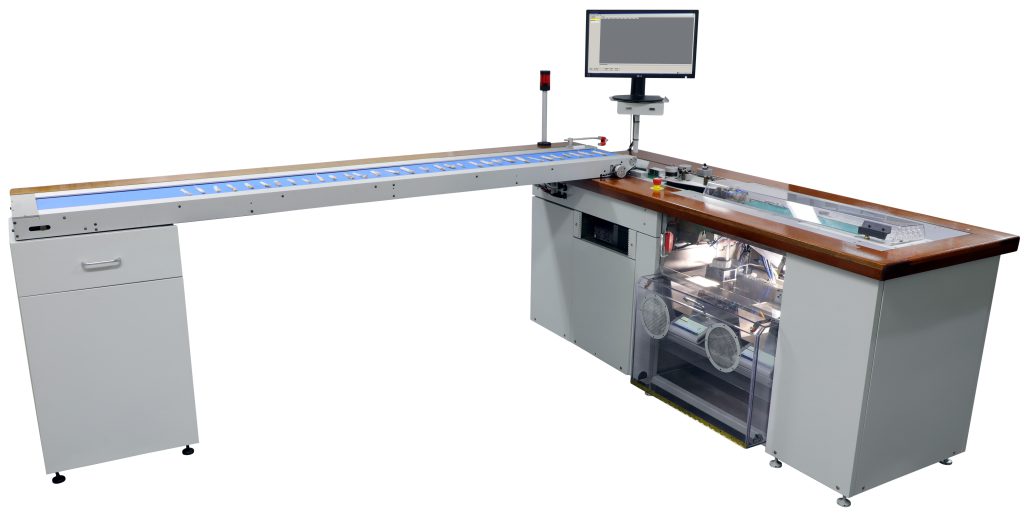

NextGen Laserscan 于 2014 年推出,并迅速成为该领域的尖端技术。它的全球客户涵盖了各种终端用户,包括大学、工厂、政府设施等。NextGen Laserscan 的创新功能和精确测量羊毛纤维直径的能力得到了市场的广泛认可。随着它的广泛应用,它已成为各行业和研究机构不可或缺的工具,为纤维测量和分析设定了新标准。

它是如何工作的?

The Wool Industry has chosen to characterise Fibre Diameter in relation to the average thickness or width of a two-dimensional projected image composed of numerous fibre snippets. In the accompanying figure1, microscopic fibre cross-sections are depicted. The non-uniform geometry complicates the definition of Mean Fibre Diameter (MFD), rendering it a more intricate task than it many initially appear.

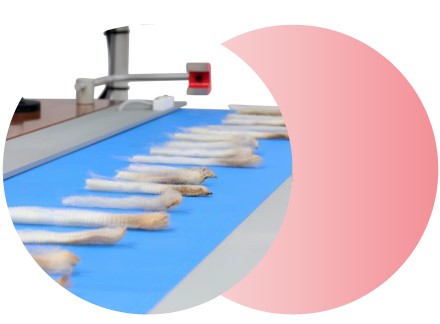

The fibre snippets are very short pieces of fibre, typically around 2mm long, which have been cut at random positions along the length of the fibre. The precise mechanism for doing this usually involves using a Minicore.

The NextGen Laserscan works by mixing fibre snippets with water and a neutral detergent called transportion fluid. The mixture then flows through a measurement cell, where the shadow cast by the wool fibre snippet in a laser beam is utilised to determine its diameter.

"新一代激光扫描仪--精确测量羊毛纤维直径

技术信息

AWTA NextGen 激光扫描仪符合国际毛纺织组织 IWTO-12-2012 标准的测试标准。

The NextGen Laserscan Model is a cutting edge solution that revolutionises precision measurements with its advanced features and user-friendly design. It boasts seamlessly intergrated electronics, ensuring optimal performance and reliability. Navigating through intricate measurements is a breeze with the simple and easy-to-use user interface, thanks to Laserscan AWIN II software, empowering users of all skill levels. The temperature-controlled cabinet guarantees stable operating conditions, enhancing the accuracy and consistency of your results. Embrace efficiency with the full automatic process, streamlining your workflow and minimising manual intervention. The NextGen Laserscan goes beyond conventional standards by employing a water based transporation fluid, not only promoting environmental sustainability but also contributing to a clean and efficient operation.

最新视频

下载内容

技术链接

材料

ATLAS - 订书钉长度和强度测量

决定精梳羊毛价值的最重要特征之一是加工后的平均纤维长度。这种长度被称为 "净度"。研究表明,Hauteur 与加工前测量的油脂羊毛的短纤长度和短纤强度密切相关。

在测量订书钉长度和强度之前,需要进行三级取样:

- 从羊毛包中抓取样品

- 从抓取的样本中提取簇绒样本

- 簇绒的订书钉准备

完成上述步骤后,用一种名为长度和强度自动测试仪(ATLAS)的仪器测量油脂羊毛的短纤维。该仪器可测量

- 订书针的平均长度(毫米)

- 订书钉长度变异系数 (CV%)

- 平均订强度(N/ktex)

- 断点位置分布图(POB%)

它是如何工作的?

长度和强度使用一种名为长度和强度自动测试仪(ATLAS)的仪器进行测量。

测量长度的方法是传送订书钉;先将钉尖穿过由八束光束组成的垂直阵列,然后电子测量传送装置在光束被订书钉打断时的移动距离。无论订书钉尺寸如何,所有订书钉都要测量长度。长度以毫米为单位。IWTO 标准要求至少测量 55 个订书钉的长度,才能得出认证结果。

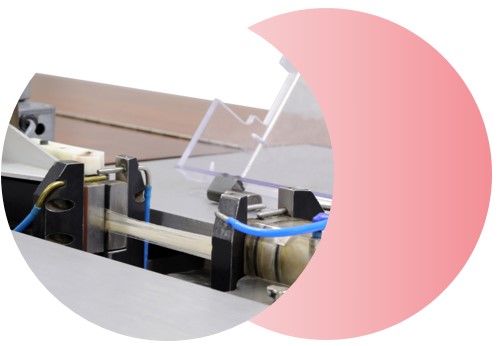

长度测量完成后,两条橡胶带将钉书针卷起,送入夹钳,夹住钉书针的顶端。然后一个钳口移开,直到钉书针的底部离开橡胶带。然后,基爪夹住订书钉的底部。顶端钳口移开,钉书针断成两截。断开钉书针所需的峰值力由连接到固定(基座)钳口的力传感器测量,单位为牛顿(N)。

就其本身而言,这一信息价值不大,因为所测量的订书钉厚度各不相同。在所有条件都相同的情况下,厚订书针比薄订书针需要更大的力才能折断。因此,折断钉书针所需的力必须与钉书针的厚度相关,这样才能更有意义地使用它。

订书钉厚度由订书钉重量和订书钉长度决定。也就是说,每毫米长度的重量克数越多,订书钉就越粗。订书钉厚度的单位是千特克斯(ktex)。总牛顿力除以千特克斯数,得出单位厚度的强度值(N/ktex)。这个数字被称为油脂订书钉强度,因为它是根据油脂订书钉重量得出的。然后使用羊毛基数和 VM 基数信息将其转换为清洁订书钉强度。

技术信息?

Atlas P3 可根据 IWTO-30-2007 标准测量一套羊毛订书机的订书长度和强度。

单个羊毛订放在传送带上,传送带将它们传送到长度测量部分。长度是通过一个能感知每根订书钉起点和终点的光阵来确定的。然后,羊毛订书针被传送到强度部分,在这里,钳子夹住订书针的两端。主食被折断,折断所需的力被记录下来。然后对断裂的钉书钉进行独立称重,以确定钉书钉断裂的位置。

根据这些信息,可以确定这组订书钉的平均订书钉长度(毫米)、订书钉长度变异系数 (%)、平均订书钉强度 (N/ktex) 和订书钉断裂位置 (%)。

最新视频

下载内容

技术链接

材料