Providing Independent and Objective Certification Services

Major services provided are sampling, testing and certifying the yield, fibre diameter, vegetable matter content, staple length and staple strength of greasy wool before it is sold.

Our key services can be categorised as:

- Wool Sampling

- Wool Testing

- Research & Development

- Certification & Reporting

- Equipment Manufacture

Raw Wool Testing

In addition, AWTA Raw Wool offers testing of raw wool, scoured and carbonised wool and speciality fibres such as Mohair, Alpaca and Cashmere and other ancillary services such as the analysis of chemical residues, dark and medullated fibre contamination tests and fleece measurements.

Yield & Fibre Diameter

AWTA Raw Wool’s key service is the independent sampling, testing and certifying of the Yield and Fibre Diameter of greasy wool before it is sold. Prior to the measurment of Yield and Fibre Diameter, a representative sample must be obtained. A core sample is taken from each bale in a sale lot under the supervision of an AWTA sampling officer. The bale weight is recorded at the time of sampling.

Staple length & Strength

One of the most important characteristics for determining the value of greasy wool is the average fibre length that will be achieved when the wool has been processed or combed into wool top. This length is known as the Hauteur (fibre length in the Wool Top). In addition, the average strength of staples is important in assessing how well the wool will perform during processing. Research has shown that Hauteur is closely correlated with the average Staple Length and Staple Strength of the greasy wool measured prior to processing.

Clean Colour

Average Yellowness is an important characteristic of wool because it is related to dyeing performance and it is not necessarily related to the colour of Greasy Wool. Considerable quantities of wool are typed as H1 (Light unscourable Colour), H2 (Medium unscourable Colour) or H3 (Heavy unscourable Colour) based purely on visual assessment of the greasy wool and are discounted in the market.

Fleece Measurement

Samples of fleece wool that are taken from individual sheep are submitted by sheep breeders and wool growers for the routine measurement of Fibre Diameter (micron) using a Laserscan instrument. This instrument provides other data in conjunction with the Fibre Diameter result, including the Coefficient of Variation of Diameter (CVD), Comfort Factor and a Fibre Curvature measurement result.

Pesticide Residues

Analysis which identifies and quantifies the residual level of lice and fly treatment chemicals in greasy wool, semi-processed wool and wool grease. The presence of heavy metals such as Arsenic can also be determined.

Wool samples are prepared and blended at one of our Raw Wool Laboratories, then sent for chemical analysis to AWTA’s Agrifood Technology division. Any chemicals present are extracted from the wool using a proprietary process and their concentrations determined using state-of-the-art equipment.

Dark & Medullated Fibre

The Dark Fibre Testing service offered by AWTA is targeted at white-wool growers who are attempting to manage contamination from exotic sheep breeds, or who wish to monitor the contamination in lots carrying a high risk of contamination.

Dark & Medullated Fibre Risk Scheme

Australian Merino wool has enjoyed a high reputation and price premium for more than one hundred years because it produced wool tops with low levels of dark and medullated fibre contamination. Recently, early and later stage processors of Australian wool have noticed increased occurrences of dark and medullated fibres in wool tops produced from Australian Merino wool.

The International Wool Textile Organisation (IWTO), through its Australian affiliate, the Federation of Australian Wool Organisations (FAWO) has initiated a program to protect the reputation of Australia’s premium Merino white wool by managing the risk of dark and/or medullated fibre contamination.

Scoured Wool

Scouring is the process of preparing and washing a batch of raw sheep’s wool to remove impurities such as grease, dirt and suint. AWTA Raw Wool is able to perform the certified testing of scoured and carbonised wool for Wool Base, Vegetable Matter Base and Mean Fibre Diameter.

Certificate Verification

The online Certificate Verification system allows holders of AWTA Test Certificates to obtain another copy via email simply by entering the certificate number, some security information and an email address into an online form. It has been provided so that people who have Certificates in their possession can check that they are legitimate. It is not designed to allow Certificates to be reproduced by those that do not own them.

Research & Development

Research & Development plays a major part in the development of AWTA Raw Wool. Based in Melbourne, the Research & Engineering group forms the largest wool measurement and engineering research group in the wool industry.

TOPMARK Benchmarking

TOPMARK is a free benchmarking service for processing mills and topmakers around the world. Independent trials have established there is a strong correlation between the predictive formulae used in this service and the processing performance of wool mills. This relationship is used to compare individual mill batches against the overall pool of data and identify areas where improvements can be made.

Electronic Services

The electronic distribution of data is an integral part of AWTA’s services. Through our Electronic Data Interchange (EDI) facilities, AWTA provide electronic data for virtually every test we undertake. Customers can improve service turnaround and reduce testing costs by transmitting sale lot and bale weight data to AWTA as part of our standard core testing service.

Electronic Data Exchange (EDI)

The electronic distribution of data is an integral part of AWTA’s services. Through our Electronic Data Interchange (EDI) facilities, AWTA provide electronic data for virtually every test we undertake. Customers can improve service turnaround and reduce testing costs by transmitting sale lot and bale weight data to AWTA as part of our standard core testing service.

IWTO Combined Certificates & OMLs

Wool Exporters and processors are required by purchasers to provide test certificates that show that a consignment of wool meet the requirments specified in a contract. These documents are also used to authorise payments by banks issuing letters of credit. Consignments often consist of numerous sale lots purchased according to the contract specifications. As it is not cost effective for the individual sale lots to be resampled and measured again as a single test, AWTA provides a service where the tests results of individual sale lots can be arithmetically combined to show the overall average measurements on a single IWTO Combined Certificate. These IWTO Combined Certificates are widely recognised and trusted throughout the wool supply chain. Similarly, the same process can be used to produce Objectively Matched Lots, however the combination of lots is restricted by minimum and maximum measurement ranges.

Online Certificate Verification

The online Certificate Verificationsystem allows holders of AWTA Test Certificates to obtain another copy via email simply by entering the certificate number, some security information and an email address into an online form. It has been provided so that people who have Certificates in their possession can check that they are legitimate. It is not designed to allow Certificates to be reproduced by those that do not own them.

Mulesing Status Reports can also be requested through this facility. Requestors need the certificate number and security code of a Combined Certificate or Mulesing Status Report in order to obtain a copy of the document.

Electronic Certificates (eCerts)

AWTA produces electronic Test Certificates and Guidance Reports as part of our standard services. These eCerts can be emailed in PDF format direct to the requestor as soon as testing is complete. The format is identical to that of the printed documents and includes multiple copies. Paper Certificates are still available by request but printing them will incur an additional fee. IWTO Combined Certificates are also available translated into Chinese.

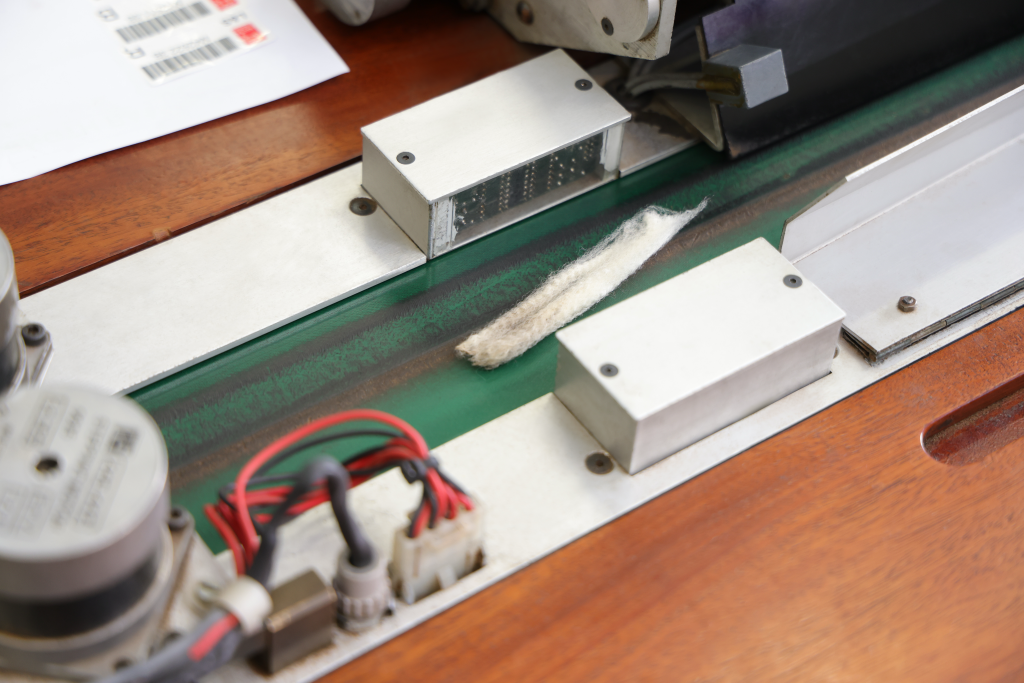

Equipment Manufacturing

AWTA Raw Wool manufactures or subcontracts the manufacturing of most of the equipment that is used in its laboratories. Much of this is specialised equipment that cannot be obtained from other sources.

AWTA is the largest supplier of wool testing equipment in the world, and has delivered equipment into Europe, Asia, New Zealand, South Africa and South America.

Raw Wool Laboratory Equipment

The measurement of wool fibre diameter can be conducted through four distinct methods as delineated by the International Wool Textile Organisation (IWTO). AWTA Ltd employes the IWTO-12 Laserscan fibre diameter analyser method for fibre diameter certification and fleece measurement services.

In 1972, CSIRO initiated the development of the first Laserscan, establishing the foundation and obtaining approval for the method from the IWTO. Subsequently, in 1996, AWTA Ltd acquired the rights to manufecture and sell the Laserscan and continued its further development.

Specialised Wool Equipment

Retailers and manufacturers now have a reliable means of objectively specifying and promoting a garment on the basis of superior comfort for the wearer, using The Wool ComfortMeter; a easy-to-use desktop instrument.

Accurately and easily measure fabrics for next-to-skin comfort values.

Retailers and manufacturers now have a reliable means of objectively specifying and promoting a garment on the basis of superior comfort for the wearer.